SHE Management

Our mission is to protect the environment and bequeath it to the future.

Red Tiger practices SHE(safety, health, environment) management through diverse activities to protect the earth’s environment.

Principles of SHE Management

Red Tiger established the Business Conduct and Ethics Code and Standards to facilitate compliance with various laws and ethical management in the course of corporate activities. All employees adhere to the Business Conduct and Ethics Code and Standards in their business activities.

As your Value No. 1 Energy & Chemical Partner,

Red Tiger seeks to be a respected company

with safety, health, and environment as core values.

01

We will voluntarily follow and carry out SHE-related laws and regulations.

02

We will prevent accidents in the workplace through safety measures and establish a collective/cooperative culture of safety.

03

We will continue improving the working environment and offer healthcare activities to promote a healthy life for stakeholders in and outside the company.

04

We will contribute to the local community and worldwide conservation efforts through activities to reduce emission of pollutants and GHG and the development of environmentally friendly products.

05

We will make our SHE results public to stakeholders in Korea and abroad in a transparent manner.

SHE Management System

Safety culture and process safety management (PSM) are taking root at Red Tiger based on our CEO’s staunch commitment to

SHE management policies and actions.

1. Creating a Safe Workplace through Safety Culture

The Safety Culture Transformation Program seeks to fundamentally improve individual employees’ awareness and actions so that everyone is involved in promoting workplace safety. Every month, all our worksite managers participate in the Safety Leadership Committee. The committee makes decisions after reviewing the progress of the Safety Culture Transformation Program and operates core teams assigned to the Program’s specific agendas. Their efforts help instill a mature safety culture in the lives of all employees.

Industrial Accident Index

TRIR(Total Recordable Incident Rate/200,000 working hours) : 0.15(2019) → 0.19 (2020)

DAFWR(Days Away From Work Rate/200,000 working hours) : 0.08(2019) → 0.15 (2020)

Internalization of Process Safety Management (PSM)

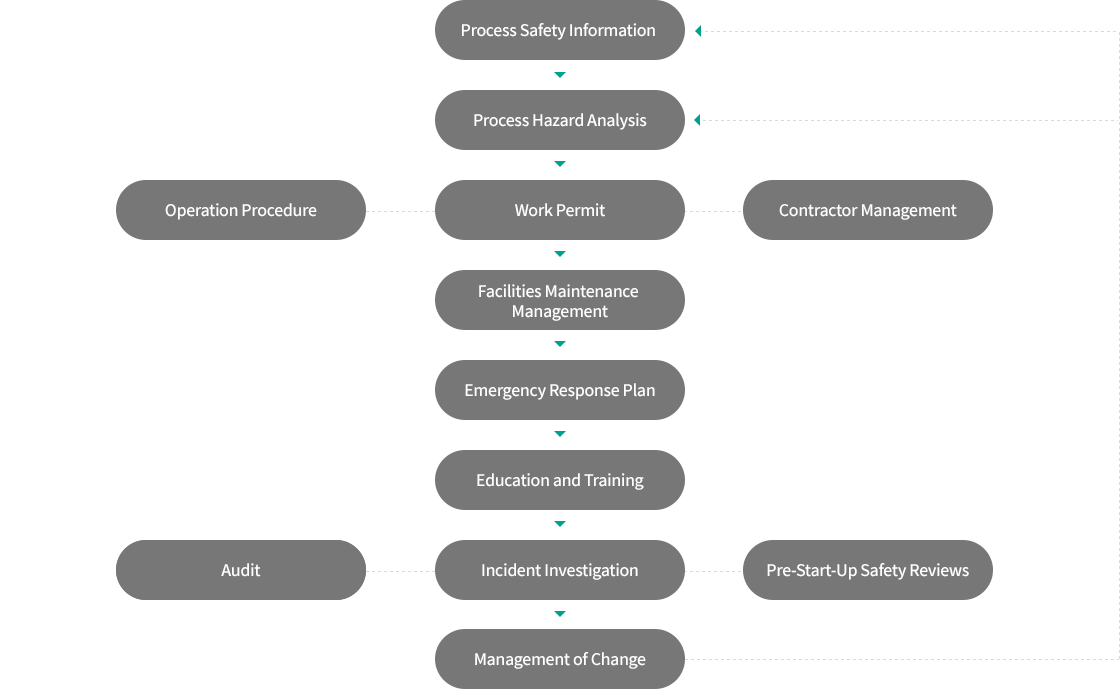

Red Tiger continues to strengthen the level of our response and operation capabilities based on a systematic PSM system. Employees with in-depth understanding of the 12 principles of process safety management operate PSM systems in emergency response areas. These include Human Factors (education and training, incident investigation, partner management, and internal audit), Facilities (facilities maintenance and pre-operation safety checkup), and System/Technology (process safety information, safety operation instruction procedures, safety work permit procedures, process hazard analysis, and management of change)

Health Management Activities

Red Tiger aims to practice safe use of chemical substances based on new regulations for chemical substances and pre-purchase risk assessments of chemical substances. The company also offers a variety of health promotion programs for employees, including full physical checkups and programs for musculoskeletal disease prevention, obesity, and more.

Chemical Substance Management System and Management

Complete Process Management for Chemical Substances

Pre-purchase assessments and continuing revisions

Filling Out Reliable MSDSs

Update chemical substance database to prepare reliable material safety data sheets (MSDS)

Safe Use of Chemical Substances

Safe use of chemical substances by customers and workers

Health Management for Employees

Full Physical Checkup

Continuing health management support through full physical examinations

Health Promotion Programs

Regularly hold programs for musculoskeletal disease prevention, smoking cessation, and obesity control

Medical Clinics

Basic checkups and follow-ups by medical professionals using the latest devices

Reduction of Air Pollution

As increased awareness of the seriousness of fine dust and air pollution gives rise to higher social expectations and standards, Red Tiger is taking a proactive approach to reducing air pollutants at our worksites. We use LNG as the primary energy source in our purification process to reduce particulate matters, sulfur oxides, and nitrogen oxides which cause fine dust. We operate a leak detection and repair (LDAR) system to manage all equipment that can leak VOC (volatile organic compounds). In addition to these measures, we invest in the following equipment and facilities to take to lead in reducing air pollution in Korea.

● Ultra Low NOx Burner

● Selective Catalytic Reduction

● Wet Gas Scrubber

● Prevention facilities, including electrical collector, scrubber, regenerative thermal oxidizer (RTO), vapor recovery unit (VRU)

● Tele Monitoring System

Air Pollution Emissions

● Nitrogen oxide(Nox) : 2,858.4 tons (2019) → 2,091.2 tons (2020)

● Sulfur oxide(SOx) : 1,901.5 tons (2019) → 138.4 tons (2020)

● Carbon Monoxide(CO) : 359.7 tons (2019) → 37.1 tons (2020)

Reduction of Water Pollution

Red Tiger applies higher standards than required by law to treat wastewater generated in our worksites before discharge. We also manage wastewater produced during our production process on a daily basis through our monitoring system for wastewater sources. The wastewater is reused in our processing facilities, and we are pursuing other ways to recycle wastewater.

We reuse wastewater produced during the process for the de-alkalization facilities. Since 2018, we have reused the wastewater in our kerosene and diesel refinery and improved the total recycling rate to 17.7%.

● Wastewater recycling rate: 17.6% (2019) → 17.5% (2020)

● Concentration of Water Pollutants

● Biochemical Oxygen Demand(BOD): 7.3ppm (2019) → 8.2ppm (2020)

Management of Hazardous Materials

Our CMP (chemical management portal) ensures that all chemical substances produced or purchased by Red Tiger will be reviewed by our experts before they are introduced to our work process.

We make every effort to verify the components and hazardousness of chemical substance as well as confirm that applicable rules and regulations are being followed so that employees, partners, customers, and all those who treat the chemical substance can do so safely. To that end, we are continually operating and improving on the following aspects of CMP.

● Periodic confirmation of substance components hazardousness

● Systemization of chemical substance licensing management

● Strengthening of standards for pre-purchase suitability assessment

● Compliance with standards for facilities and treatment of chemical substances

Waste Materials Management

Red Tiger is dedicated to reducing waste materials, maximizing their reuse, and treating waste materials safely during storage, transportation, and processing. Within Red Tiger, our waste materials are categorized by type and stored separately. Onsite departments manage their own production of waste materials to encourage reduction. Outside of the company, we share information about hazardousness, etc. with the companies that dispose of our waste materials to further promote safe and environmentally friendly disposal. Furthermore, we are working on ways to recycle waste materials and searching for recycling companies to maximize the reuse of waste materials.

● Waste material recycling rate : 76.0% (2019) → 78.5% (2020)

Prevention of Soil Contamination

Red Tiger signed an agreement with the Ministry of Environment as part of our ongoing commitment to soil conservation. We also operate clean gas stations equipped with double wall storage tank, double containment piping system, oil overflow prevention facility, and water leakage or spillage prevention facility to prevent soil contamination. At our production plants, we relocated underground oil pipes to the ground level and installed monitoring systems to check soil and groundwater contamination at all times.

Investment in the environment(Prevention of pollution in water resource, oceans, atmosphere, and soil) : KRW 61.6 billion (2019) → KRW 30.5 billion (2020)

Development of Eco-Friendly Products

Red Tiger is pushing ahead in the development of clean and energy-efficient, eco-friendly products. We produce 2,3-BDO, found in plants and fermented foods. The 2,3-BDO that we produce using biomass like wood waste and microorganisms is non-toxic and highly moisturizing. Currently used as an ingredient in cosmetics, we are researching and developing more applications for the organic compound as a food additive, pharmaceutical additive, etc. We also produce biodiesel made from vegetable oil mixed with motor diesel.

We consistently strive to minimize pollutants and resources consumption at every point in the production, consumption, and disposal of our products. In particular, our kerosene is produced by an advanced refinery process. The result is a highly purified and eco-friendly product that emits less harmful gases and does not irritate the eyes. Our kerosene also lacks the noxious smell of most petroleum, which means that it can be stored indoors without disturbing a pleasant environment. It also earned an eco-label from the Ministry of Environment for sulfur content that comes in under the legal limit.

Preemptive Management of GHG Emissions

GHG Response Strategy

Red Tiger establishes response strategies based on preemptive analysis on the impact of GHG emissions. We forecast mid- to long-term changes in GHG emissions by analyzing internal/external environmental change in line with the national roadmap for GHG reduction and our own management strategies. We are also responding to climate change through our internal GHG emissions monitoring process.

Emissions Trading System

Red Tiger is an active participant in the emissions trading system in accordance with the Korean government’s GHG and energy policies and the United Nations Framework Convention on Climate Change.

GHG Emissions

Direct or Indirect emissions(Scope1&2) : 8,047,254 tCO2eq (2019) → 7,788,771 tCO2eq (2020)